Securing the Defense Supply Chain

Expanding our access to critical minerals and the resources necessary to process them

What makes a mineral “critical”?

The US is dependent for nearly 90% of rare earth elements (REEs), which are needed for everything from electric vehicles (EVs), to storage batteries for the national energy grid, fighter jets and all major weapons platforms – putting the future of our economy, clean energy, and national defense at stake.

Aluminum goes into 80% of all aircraft, including F-16s, and is heavily used in energy platforms such as solar panels and wind turbines

Beryllium is crucial in helicopters’ optical systems as well as in concentrator photovoltaic cells that generate electricity from solar power

Molybdenum is– essential in the production of aircraft engines, rockets, and missiles, as well as renewable energy generation including wind, solar, nuclear, and hydro

Copper, while not on the official Critical Mineral list, holds the key to many essential minerals and is an essential element for the nation’s security and clean energy efforts; for example, a single electric vehicle requires 117+ pounds of copper and there are 8 miles of copper wire in a single Boeing Apache Helicopter

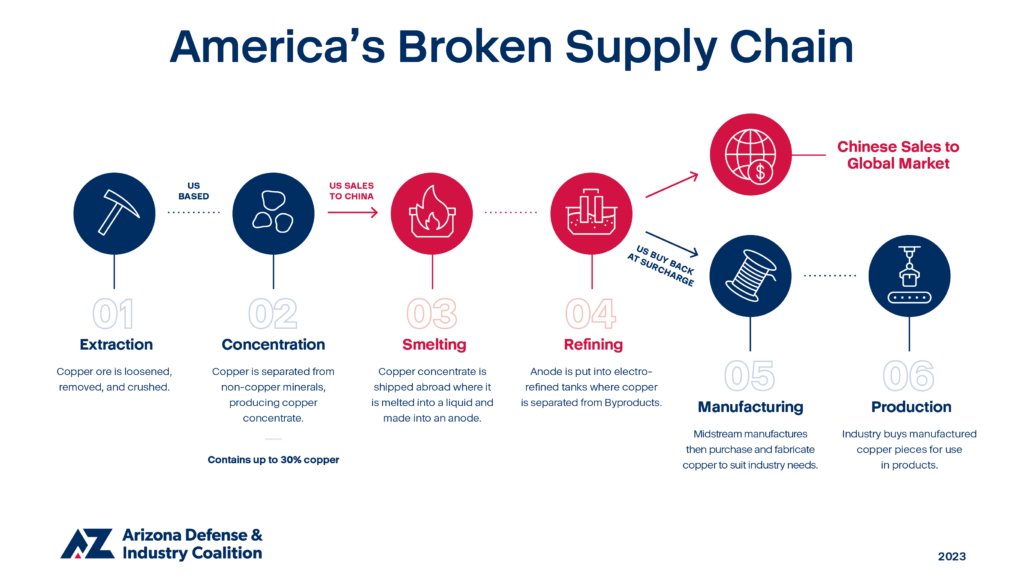

Dangerous Dependencies

It is imperative that the US brings critical mineral production home, but current US infrastructure and policy hinders our nation’s ability to execute. Consequently, the US relies on critical mineral supply from foreign adversaries, raising ongoing risks to our national security.

- Russia is a leading supplier of minerals and rare earths, mining 27,000 tons of rare earths a year and holds 10.4% of the world’s reserves

- China is the global leader in rare earths mining, refining, and component manufacturing; mining 140,000 million tons annually and holding 38% of the world’s reserves

- There are currently zero rare earths processing plants in America and only two copper smelters. This means that once the minerals are out of the ground, they are sent overseas where the midstream processing that is separation, purification, and metal-making takes place.

How Arizona is Working to Secure the Defense Supply Chain

While the US is heavily import-dependent on critical minerals, actions can be taken to develop viable mining processes to reduce the country’s dependency on foreign adversaries like China and Russia. To do so, change must start locally.

That is why the Arizona Defense & Industry Coalition has brought together defense, green tech, mines, education, and environmental groups to address these growing supply chain reliance.

You can learn more about our research in our whitepaper.